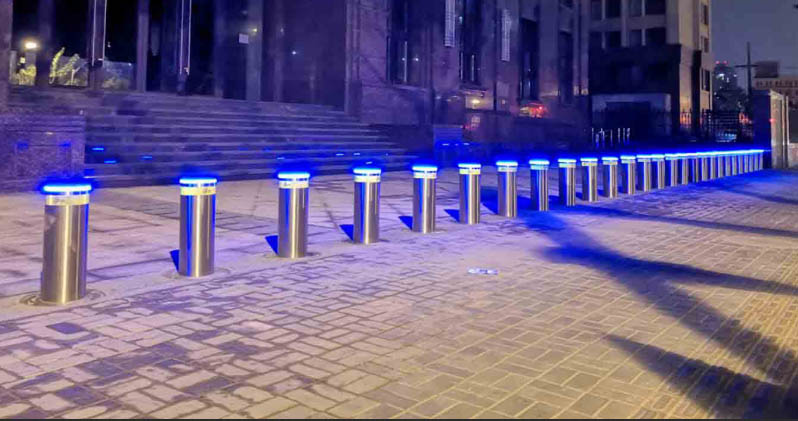

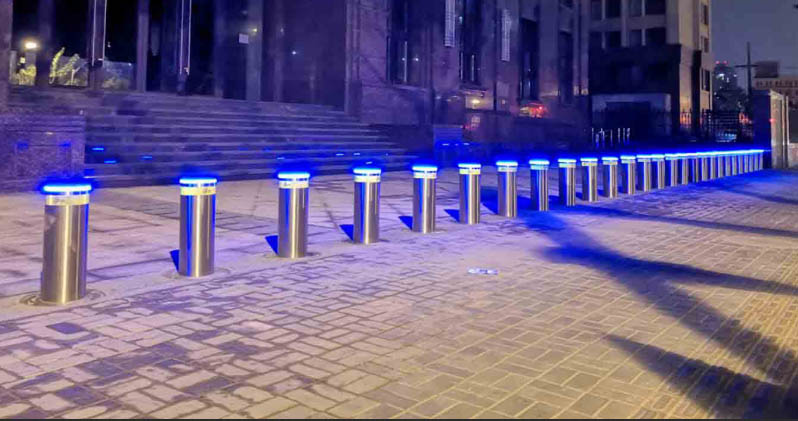

High-duty cycle hydraulic bollard system ensures long-lasting performance and heavy use.

Hydraulic Bollard Features

1. The obstacle can be lowered by a manual operation directly on the hydraulic pump in case of power failure

2. The bollard finishing is available in painted steel and in brush stainless steel

3. The control unit is housed in a cabinet which could be up to 80m remote

4. Easy underground pit laying and limited excavation

5. Sleek design and pleasing aesthetics

6. High-duty cycle, ensuring lasting performance and intensive use

7. Quick and easy to install because the foundation box can be assembled on site

8. Long service life

9. Integrated hydraulic unit

10. Equipped with an anti-vandal function, which detects a forced command, to reset the bollard and activate an alarm

Hydraulic Bollard Applications

Embassies

Consulates

Military installations

Airports

Railway stations

Bus stations,

Oil & gas refineries

Hydraulic Bollard Parameters

| System Control |

Electric hydraulic drive |

| Power Supply |

AC110V~240V, 50/60hZ (control voltage DC24V) |

| Material |

#304 stainless steel ( #201, #304, #316 stainless steel optional) |

| Diameter |

φ168mm, φ219mm, φ273mmoptional |

| Thickness |

6mm, 8mm, 10mm, 12mm, 15mm, 20mm optional |

| Box Round Diameter |

φ370mm. Height: 990mm |

| Through Pressure |

Bearing over an 80-ton container truck |

| Outside Bollard Height |

600mm |

| Remote Control Range |

≤ 30 meters |

| System Power |

3.7 KW |

| Rising Time |

≤3~5 seconds (adjustable) |

| Falling Time |

≤ 3 seconds (adjustable) |

| Working Temperature |

-35ºC~75ºC |

| Storage Temperature |

-10ºC~65ºC, anti-rain, anti-dust, anti-moisture |

The Design

Project Case

Please leave a message if you are interested in this model